While this is not a new concept as a type of bicycle. Think of the old Bridgestone XO-1's from back in the day. And more recently touted by some folks up in Seattle (who may be producing some of the nicest tires for Allroad bikes out there). But we here at Bantam Bicycle Works feel like we have it nailed down. We think that you will feel the same.

Details:

Rando-gravel geometry, optimized for wide supple tires. Low trail front end, with the idea that if you are going to be carrying stuff with you, you'll most likely be loading up the front before the rear. Spry and nimble with or without a load.

Each frameset will be custom sized, and the tubing specially select for the customer.

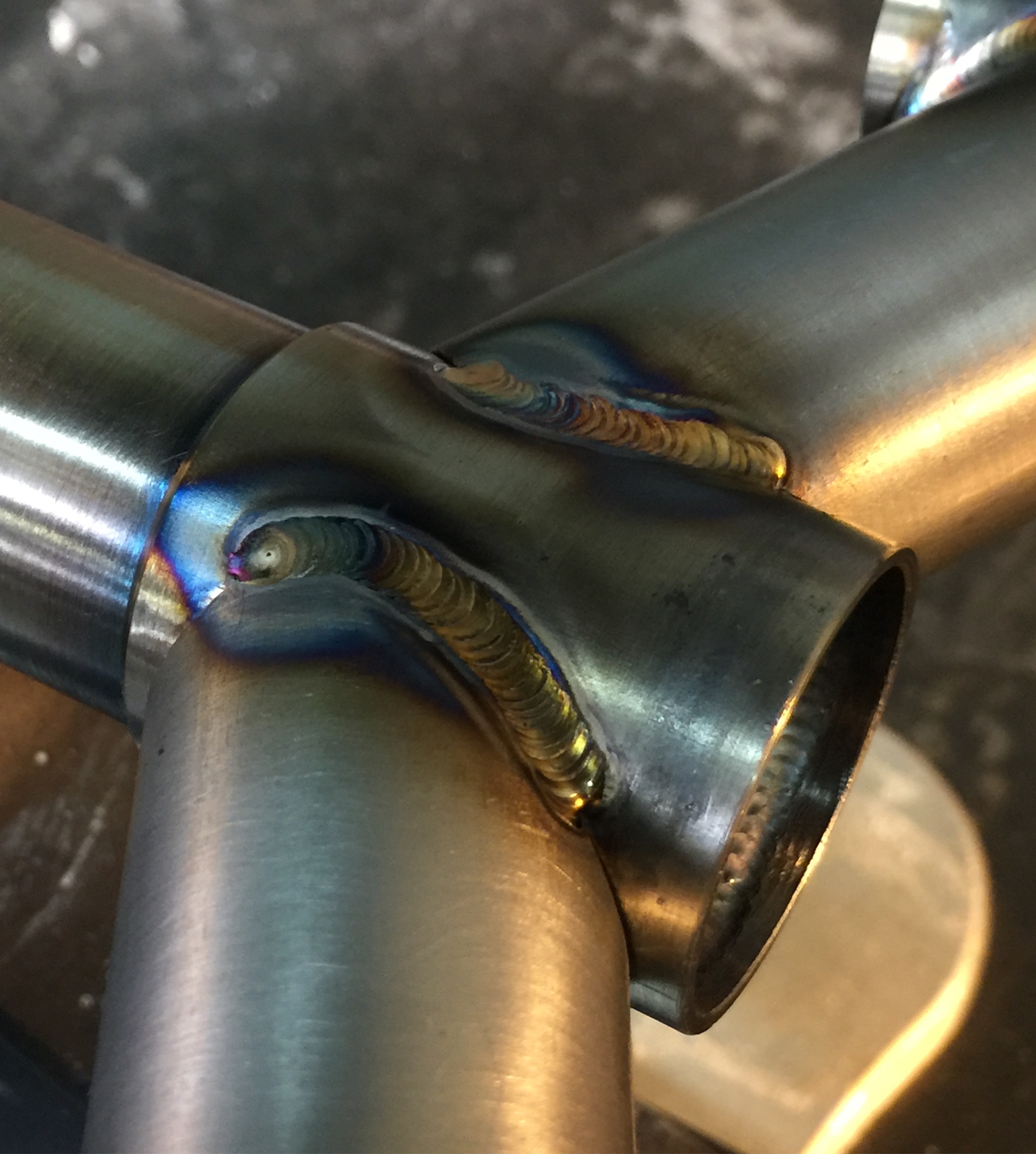

TIG welded construction.

Clearance for 26x2.3" or 650x48b tires. They're real close to being the same diameter. So switching between won't affect your geometry and handling significantly. (You certainly could run a different tire size than these, but we're not making any promises of how well it might work).

Disc brakes, ISO mounts, front and rear. Lowmount disc dropouts in the back. Cable stops and guides for mechanical disc brakes as standard (see options, down below).

Spacing for a 100mm front hub and 135mm rear hub, standard quick releases.

Head tube and fork for a 1.125" threadless headset (straight steerer).

68mm threaded bottom bracket shell.

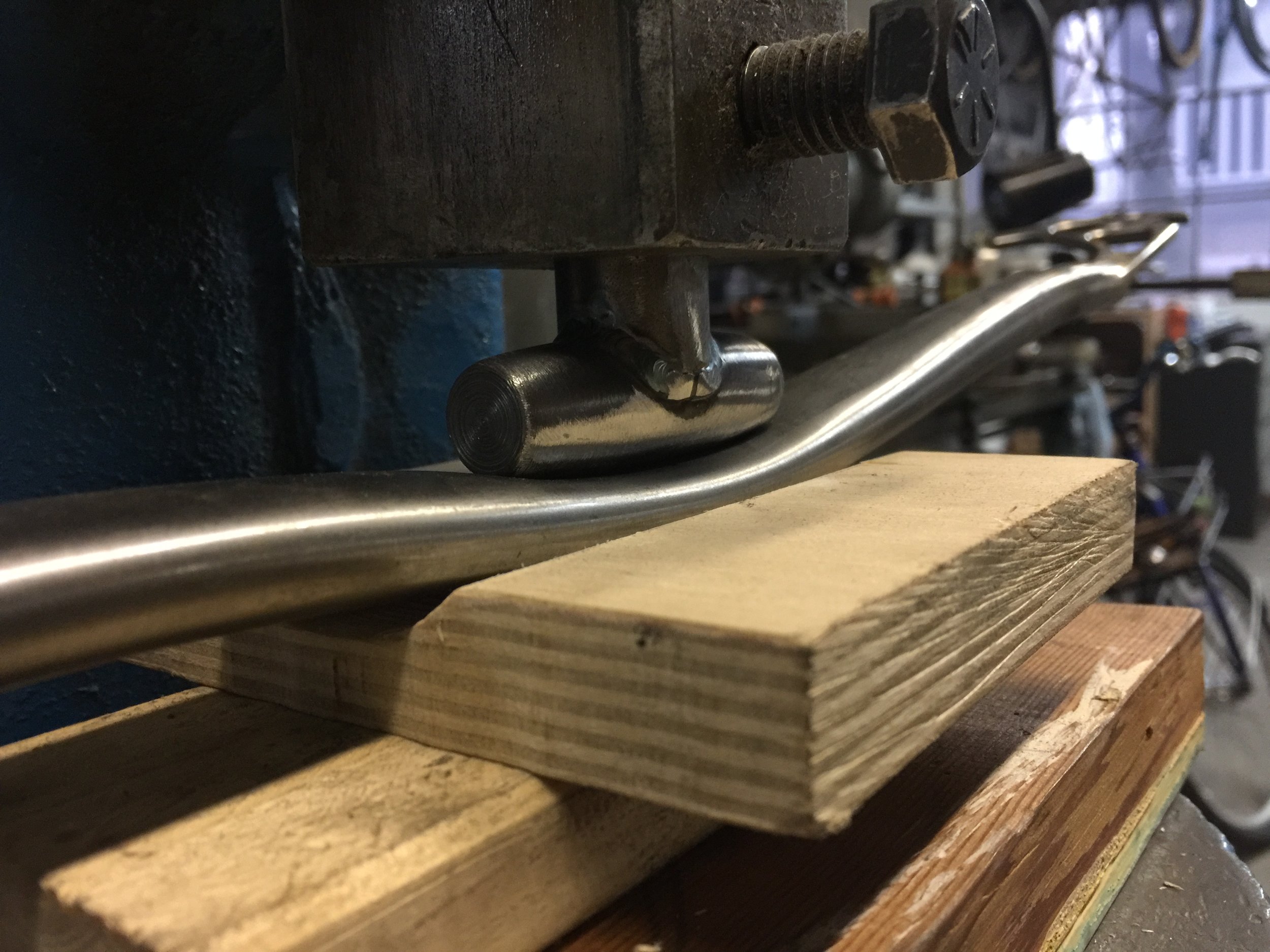

Uni-crown, straight blade fork.

Bosses for three water bottle cages on the frame (two inside the main triangle, one under the down tube).

Eyelets for racks (front and rear) and fenders (at the dropouts and at the bridges).

Will take a 30mm seat post clamp, and a 27.2mm seat post.

Single color powder coat (any color you'd like), with sprayed on decals and clear coat.

Options:

Housing guides for hydraulic brake lines (no extra charge).

Additional rack mounts, front and/or rear (+$50/pr).

Reinforced wire ports for running taillight wires internally (+$25).

Metal head badge (+$50).

We can also do custom racks and stems (additional charge, cost depending on design).

Parts for your new bike. We are happy to provide you with a partial or full build kit for your bike at a reasonable cost (definitely an additional charge).

The how to buy one:

So, one of these framesets will put you back $1500. If you want to get on board, we'll be taking non-refundable deposits of $750 to get you into the queue. We'll be taking deposits until the end of January 2017 for this run of frames. We are currently looking at delivery in early 2018. Space is limited, due to our production capacity, so there are only going to be eight available spots in this batch.

Thanks, and we are looking forward to hearing from you.